Ethylene glycol production

The main by-products are diethylene glycol and glycol (i.e., triethyl glycol). The formation of high concentration glycol is inevitable because the reaction of ethylene oxide and ethylene glycol is faster than that of water.

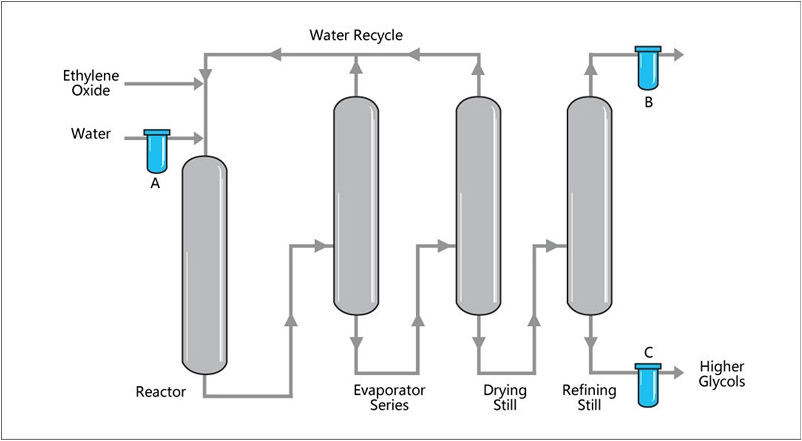

The factory maintains the conversion rate by using excessive water, promoting the production selectivity of ethylene glycol

Ethylene glycol is refined through a vacuum fractionation and excess water is removed and recycled in a series of evaporators

Pollution control

Both solid and semi-solid pollutants are introduced into the production process with the following substances

Add raw material water

A byproduct produced during hydrolysis

Controlling the fluctuation of pollution levels during ethylene glycol production will bring the following benefits

Optimized productivity

Ensure final product meets technical requirements